THE EVOLUTION & INNOVATION OF JAPANESE STAINLESS STEEL

Drawing from its rich history of traditional forging methods and constant thirst for advancement, Japan has pioneered numerous developments in stainless steel.

THE EVOLUTION & INNOVATION OF JAPANESE STAINLESS STEEL

A BRIEF HISTORY

Stainless steel is a pivotal innovation that revolutionized many the cutlery industry. Stainless steel emerged in the early 20th century, with British metallurgist Harry Brearley making the first stainless steel in 1913. Although this invention was originally intended for gun barrels, it quickly found various other applications due to its exceptional corrosion resistance. Around the same period, Japan was undergoing rapid modernization and Westernization, and the adoption of Western steelmaking technologies was part of this transformative process. While it was initially developed in the West, it didn’t take long for Japan to harness the potential of this versatile material by combining it with its long tradition of metallurgical mastery.

JAPANESE STEEL EVOLUTION

Post-Meiji period, Japan embraced the Western methods of steel production, giving birth to several large-scale steel companies like Nippon Steel. Although Japan was initially import-dependent for its stainless steel needs, the demand for durable, corrosion-resistant materials during WWII prompted the country to explore local stainless steel production. Post-war economic recovery provided a significant boost to the steel industry in Japan, making it a leading stainless steel manufacturer worldwide.

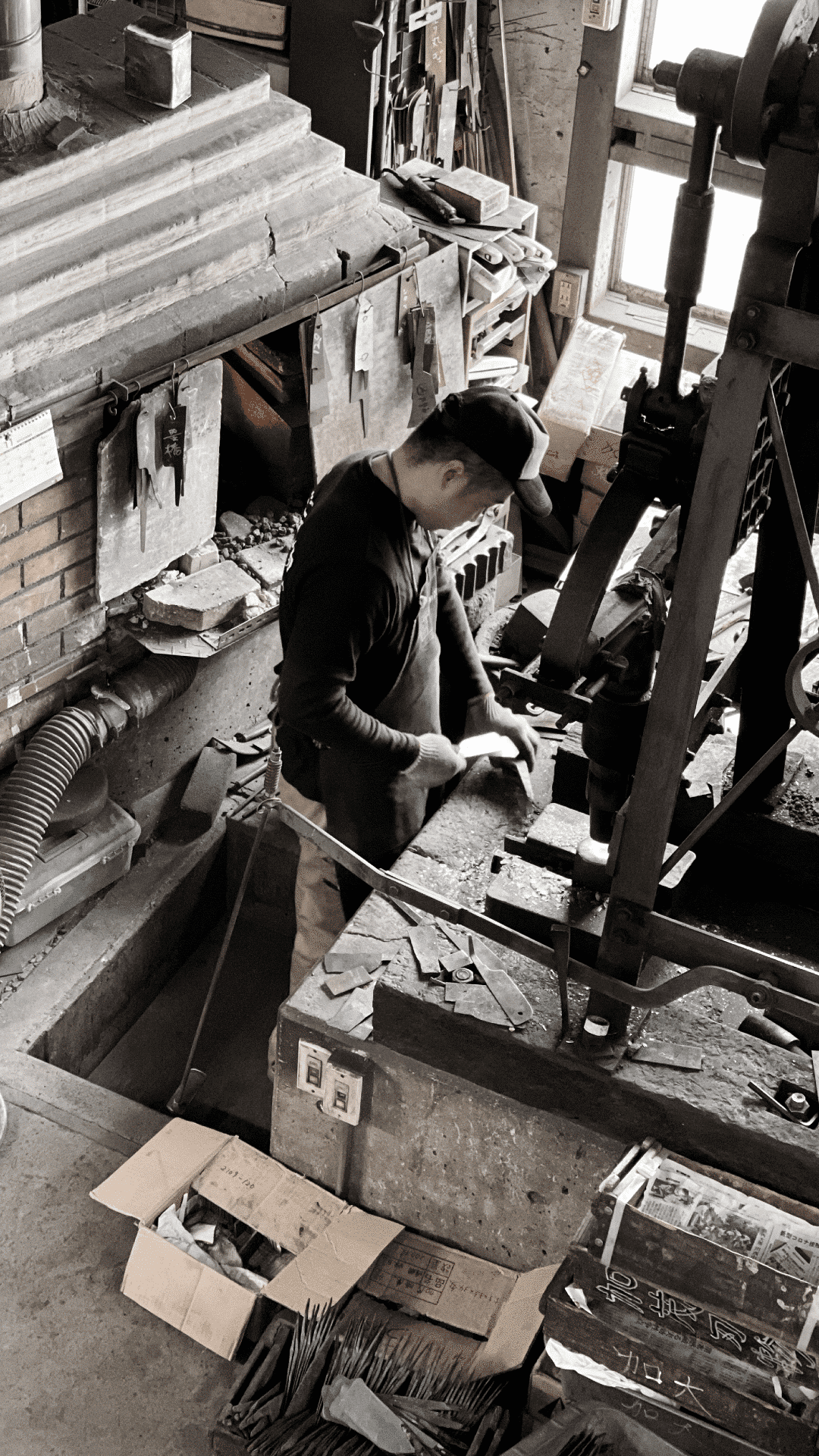

Japanese stainless steel’s uniqueness lies not only in its quality but also in the blending of modern technology with traditional forging methods. From the time of the samurai, Japan has had a rich history of blade-making, renowned for the katana’s exceptional hardness and sharpness. The secret behind such craftsmanship is the unique forging and folding technique known as “tatara.” The application of these ancient methods to modern stainless steel processing resulted in products with unparalleled sharpness and durability. VG10 is one of most well known stainless steels. It is made when carbon, chrome, molybdenum, vanadium, and cobalt are added on high-selected virgin steel. VG10 knives hardly get rusted and enable us to cut for long time. The rare metal cobalt creates high hardness and high abrasion resistance.

REGIONS OF METALWORK

Japan’s stainless steel industry extends far and wide and each has its own unique history. Together, they propel Japan’s global reputation in stainless steel manufacturing. Listed are a few significant hubs of production:

- Sakai City: Located in Osaka Prefecture, Sakai City has been the heart of Japanese cutlery production since the 16th century. The city specializes in kitchen knives, with many of its smiths now using stainless steel to make world-renowned blades.

- Niigata: Known for its rich history in metalwork, Niigata produces a variety of stainless steel products. The city of Sanjo, within Niigata Prefecture, is renowned for its blacksmithing traditions and is home to many small workshops producing high-quality stainless steel knives.

- Seki City: Situated in Gifu Prefecture, Seki City boasts an ancient sword-making tradition dating back to the Kamakura period (1185-1333). Today, Seki is famous for its top-tier stainless steel kitchen knives and scissors, maintaining its reputation as a leading blade-making city.

- Miki City: In Hyogo Prefecture, Miki City has been a hub for toolmaking since the Edo period (1603-1868). This heritage extends to the present day, with many workshops now producing excellent stainless steel tools and knives.

- Tokyo: The capital city is home to a number of renowned blacksmiths and blade-making workshops producing high-quality stainless steel cutlery. Tokyo’s Kappabashi Kitchen Town is particularly famous for selling these top-grade stainless steel knives.

- Takefu: Located in the Fukui prefecture, is one of Japan’s primary regions known for metalwork, particularly for its high-quality knives. The blacksmiths in Takefu have adapted their age-old blade forging techniques for modern stainless steel. Today, it’s home to Takefu Special Steel Co., which produces an assortment of stainless steels used in various high-end applications, including knives, medical equipment, and industrial machinery. Each of these regions, like Takefu, carries forward a centuries-old tradition, blending it with modern methods to create stainless steel products of unparalleled quality.

RECENT STAINLESS STEEL DEVELOPMENTS

Gingami, or Silver Paper steel (also called Ginsan or Gingami No.3) is another important steel in Japan. This steel type is favored by knife artisans for its ability to simulate the qualities of traditional carbon steel while still providing the easy maintenance of stainless steels. This includes a good balance of hardness and toughness, exceptional edge sharpness, and, crucially, a high level of corrosion resistance that carbon steel lacks. With a composition of carbon, chromium, and molybdenum, Gingami steel can be hand-forged and sharpened to a fine edge, much like traditional carbon steels. It has found particular favor among knife makers who seek to blend the aesthetic and performance qualities of traditional Japanese cutlery with the lower maintenance benefits of stainless steel.

In recent years, powder metallurgy has presented yet another breakthrough. Powdered steels, such as the high-speed powder steel is gaining prominence in its use in tools and more recently in knife making. Powder metallurgy offers greater control over the material composition and microstructure, leading to superior performance characteristics. This technique involves heating metallic powder under intense pressure to forge the steel, resulting in a homogeneous distribution of carbides for improved hardness and edge retention.

The integration of traditional practices with contemporary materials has set the stage for continuous evolution in Japanese stainless steel production. Varieties like VG10 and VG-MAX, known for their excellent edge retention and resistance to wear, are becoming popular choices for premium cutlery.

Another recent advance in Japanese steel-making is the development of ZDP-189, a powder metal steel produced by Hitachi Metals. This ultra-high carbon stainless steel boasts an impressive hardness of up to 64 HRC, making it one of the hardest stainless steels available today.

SG2, also known as R2, is a high-carbon stainless steel that originates from Japan and is widely used for premium kitchen knives. It is a product of the powder metallurgy process, which allows for the uniform distribution of carbides, enhancing the steel’s hardness, edge retention, and durability. The high-carbon content of SG2/R2 steel makes it possible to achieve a Rockwell hardness of 62-64 HRC, ensuring a sharp edge lasts longer. Due to its superior performance characteristics, it is considered one of the most sought-after steels among professional chefs and culinary enthusiasts worldwide. The popularity of new steels further underline Japan’s ability to fuse traditional practices with modern technological advancements. Japan remains a positive force to the ongoing evolution of the world’s stainless steel industry.

CONCLUSION

In conclusion, the story of stainless steel in Japan is one of successful assimilation, innovation, and improvement. Drawing from its rich history of traditional forging methods and constant thirst for advancement, Japan has pioneered numerous developments in stainless steel. The continual evolution of alloys and the introduction of powder metallurgy have pushed the boundaries of what is possible with stainless steel. Despite modern advancements, the heart of Japan’s stainless steel industry remains deeply rooted in its history, maintaining a harmonious balance between the old and the new.

KULUR ROLL

KULUR ROLL COOKING

COOKING